A Comprehensive Guide to Carbon Steel ERW Pipe and Trusted API 5L Pipe Suppliers

In the global industrial landscape, steel pipes play a pivotal role in driving infrastructure, energy, water management, and construction projects. Among the various types available today, the Carbon Steel ERW Pipe stands out as a widely used and highly dependable option for numerous applications. At the same time, businesses across oil & gas, petrochemical, and heavy industries continue to rely on professional and certified API 5L Pipe Suppliers to ensure smooth and safe operations. Understanding these two elements is essential for organizations planning any major engineering or pipeline project.

What Makes Carbon Steel ERW Pipe a Preferred Choice?

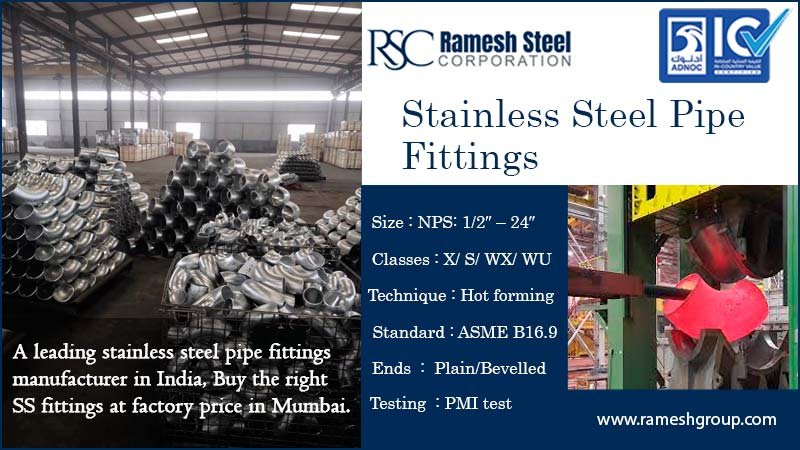

Carbon steel has long been popular in industries due to its high strength, durability, and cost-effectiveness. When manufactured using Electric Resistance Welding (ERW), carbon steel pipes gain additional stability and precision. The Carbon Steel ERW Pipe is produced by cold-forming steel strips into a cylindrical shape, followed by passing an electric current across the edges to weld them together. This method results in a clean, smooth, and uniform weld seam.

Key Advantages of Carbon Steel ERW Pipes

- High Strength and Reliability

ERW pipes deliver excellent structural integrity, making them suitable for transporting water, oil, gas, steam, and various industrial fluids. - Cost-Effective Manufacturing

Compared to seamless pipes, the production of Carbon Steel ERW Pipes is comparatively economical without compromising strength, making them highly preferred for large-scale projects. - Superior Weld Quality

Modern ERW technology ensures that the weld seam is consistent and robust. With advancements in non-destructive testing, ERW pipes now match the performance of seamless pipes in many applications. - Smooth Surface and Dimensional Accuracy

The precision offered by the manufacturing process results in high-quality pipes that fit perfectly in complex systems, reducing the need for excessive machining. - Versatility Across Industries

From water pipelines and fencing structures to automobile frameworks and engineering applications, these pipes serve diverse needs across multiple sectors.

Applications of Carbon Steel ERW Pipe

The rising demand for Carbon Steel ERW Pipe is driven by its multipurpose nature. Industries value these pipes for:

- Oil and Gas Pipelines

Suitable for low-to-medium pressure applications. - Structural and Engineering Uses

Ideal for columns, scaffolding, frameworks, and truck/body manufacturing. - Water and Wastewater Transport

Their corrosion-resistant properties make them suitable for municipal water systems. - Fencing and Construction

Lightweight yet strong, ERW pipes are commonly used for fencing, gates, and architectural projects. - Automobile Manufacturing

Manufacturers use ERW pipes in exhaust systems, chassis, and impact-resistant components.

Their ability to deliver consistent performance in different environments makes them an industry staple.

Why Choosing the Right API 5L Pipe Suppliers Matters

For demanding industries such as oil and gas transmission, selecting reliable API 5L Pipe Suppliers is crucial. The API 5L specification, developed by the American Petroleum Institute, governs the quality, chemical composition, and mechanical properties of line pipes used for transporting gas, water, and petroleum products.

What Do Good API 5L Pipe Suppliers Offer?

- Certified and Compliant Materials

Reputable suppliers stock API 5L pipes in various grades like PSL1 and PSL2, ensuring strict adherence to international standards. - Wide Range of Options

From seamless to welded pipes and from standard to high-strength grades, good suppliers offer comprehensive solutions for specialized industrial needs. - Testing and Quality Assurance

Trusted API 5L Pipe Suppliers provide third-party inspection reports, mill test certificates, ultrasonic testing, hydro testing, and more, guaranteeing product safety. - Fast Delivery and Strong Inventory

Industries often work on tight deadlines. A dependable supplier maintains large stock levels to ensure timely delivery for urgent requirements. - Technical Expertise and Support

Professional suppliers assist with material selection, grade comparison, and engineering requirements, ensuring clients get the right pipe for their specific applications.

Carbon Steel ERW Pipe vs. API 5L Line Pipe: Understanding the Difference

While both carbon steel ERW pipes and API 5L line pipes serve similar purposes, they differ in their intended applications and standards.

- Carbon Steel ERW Pipe can be used for structural or fluid transport applications and are available in various grades depending on requirements.

- API 5L Pipes strictly adhere to pipeline transport standards and are ideal for high-pressure oil and gas pipelines.

Often, companies source ERW pipes that also comply with API 5L specifications, merging cost-efficiency with regulatory compliance.

Final Thoughts

As global infrastructure demands continue to grow, the importance of selecting high-quality pipes and trustworthy suppliers becomes increasingly significant. The Carbon Steel ERW Pipe remains one of the most reliable options for structural and fluid transportation applications. At the same time, industries that rely on pressurized pipeline systems must work closely with certified and experienced API 5L Pipe Suppliers to ensure safety, compliance, and long-term performance.

Whether you are constructing a massive oil pipeline network or a modern industrial facility, choosing the right materials and partners will ultimately determine the efficiency and durability of your operation.